INSIGHTS

How to Choose the Right PCAP Touchscreen Manufacturer in 2025

DISPLAX Team | June 25, 2025 | 5min

This article outlines the most important factors for selecting a PCAP (Projected Capacitive) touchscreen manufacturer in 2025. The article covers product quality, customization, support, and key differentiators. Learn how to choose the right supplier - whether you're in the US, Europe, Latin America, Middle East, or Asia-Pacific - and avoid costly mistakes.

This article outlines the most important factors for selecting a PCAP (Projected Capacitive) touchscreen manufacturer in 2025. The article covers product quality, customization, support, and key differentiators. Learn how to choose the right supplier - whether you're in the US, Europe, Latin America, Middle East, or Asia-Pacific - and avoid costly mistakes.

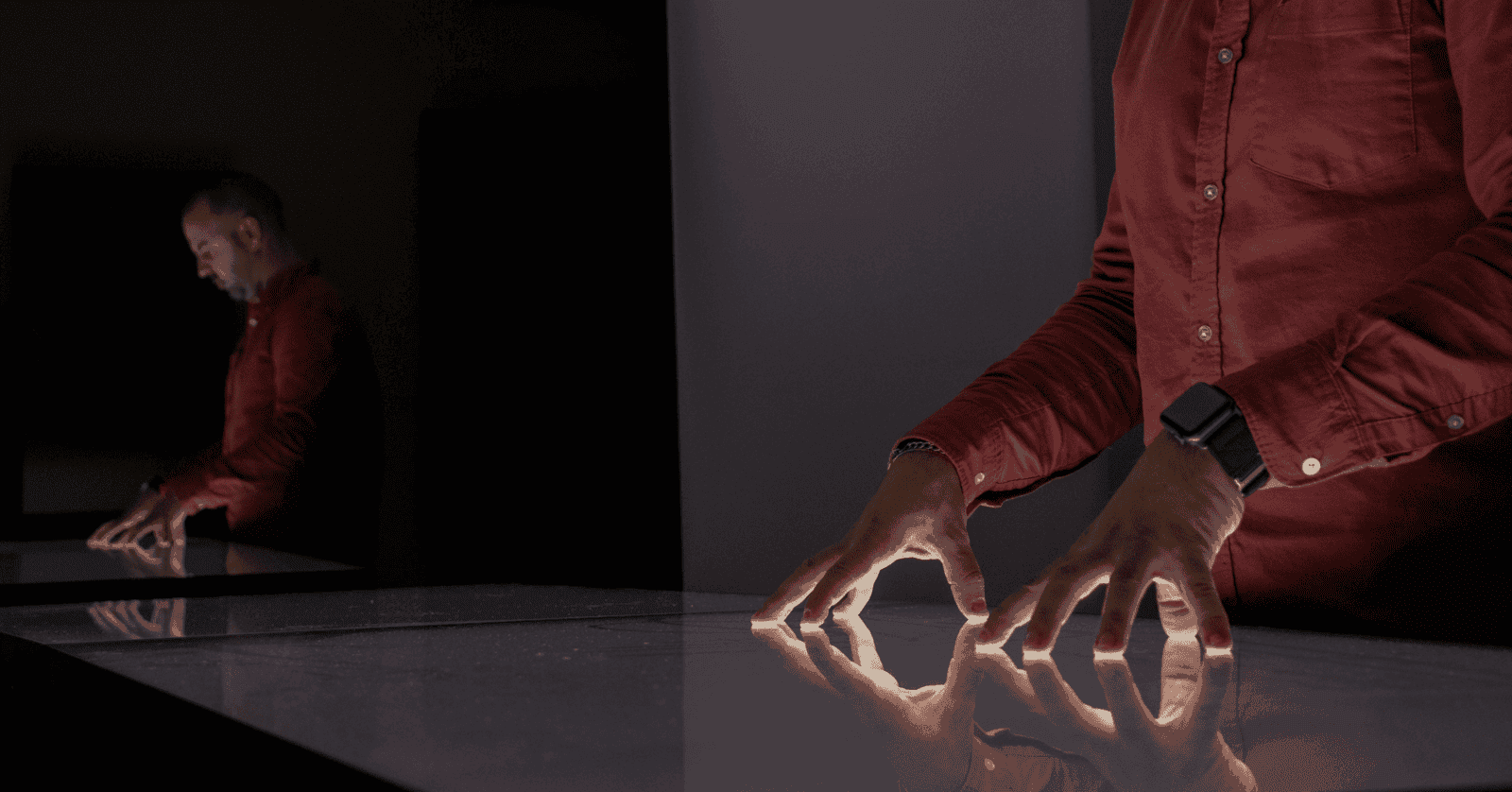

Touchscreens are everywhere, powering kiosks, digital signage, medical equipment, EV chargers, industrial machines, and more. But in 2025, not all touchscreen technology - or suppliers - are built the same.

With the rapid exit of key players like Zytronic from the market, and the influx of low-cost alternatives, choosing the right PCAP touchscreen manufacturer is more critical than ever. Whether you're an OEM, system integrator, or product engineer, this guide will help you identify what really matters - and how to make the right long-term choice for your project.

Touchscreens are everywhere, powering kiosks, digital signage, medical equipment, EV chargers, industrial machines, and more. But in 2025, not all touchscreen technology - or suppliers - are built the same.

1) What Is a PCAP Touchscreen Manufacturer?

1) What Is a PCAP Touchscreen Manufacturer?

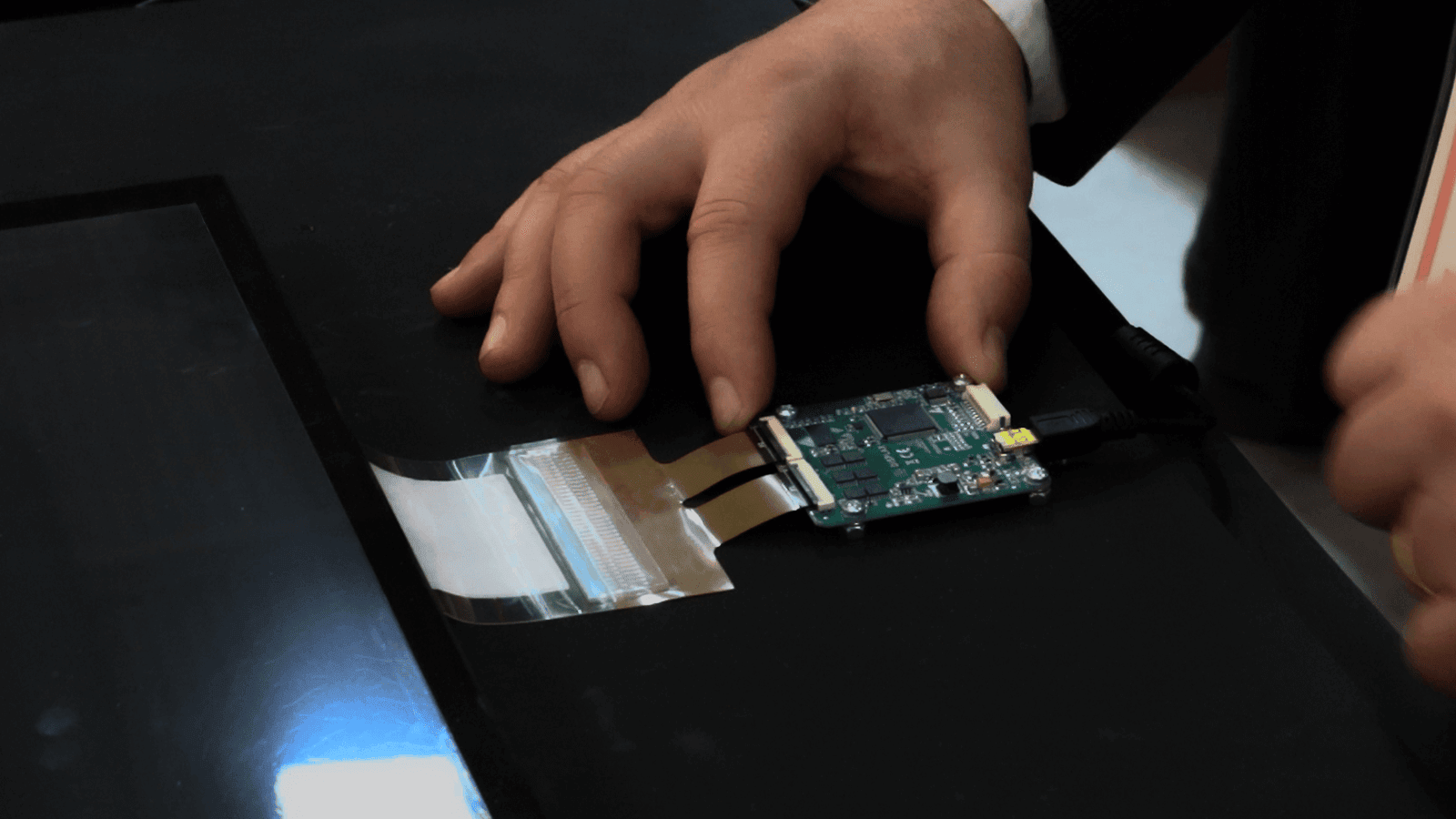

A PCAP (Projected Capacitive) touchscreen manufacturer designs, builds, and assembles the key components behind interactive touch devices. This includes:

The touch sensor (usually ITO, wire, or metal mesh-based)

The touch controller (which detects touch input and communicates with the device)

And often, the glass and lamination process (the interface the user actually touches)

A true PCAP manufacturer develops these components in-house or controls the full supply chain — rather than assembling parts from third parties.

A PCAP (Projected Capacitive) touchscreen manufacturer designs, builds, and assembles the key components behind interactive touch devices. This includes:

The touch sensor (usually ITO, wire, or metal mesh-based)

The touch controller (which detects touch input and communicates with the device)

And often, the glass and lamination process (the interface the user actually touches)

2) Why Manufacturer Choice Matters (Globally)

2) Why Manufacturer Choice Matters (Globally)

Choosing the wrong supplier can lead to:

- Incompatibility with your system

- Poor durability in outdoor or industrial environments

- Long lead times or unstable supply chains

- Weak support or integration help

- Unclear product roadmaps

And in today's climate, with supply chain shifts, AI-driven UX expectations, and demands for local support, picking a reliable PCAP partner is key to your success in any region.

Whether you're based in:

- North America

- Europe

- LATAM

- Middle East

- Asia-Pacific

Or your product application is for:

- Industrial equipment, EV, kiosk

- Retail, corporate, AV, outdoor

- Banking, public systems, healthcare

- Transport, entertainment, energy

- Gaming, consumer, manufacturing

…the same critical considerations apply.

Choosing the wrong supplier can lead to:

- Incompatibility with your system

- Poor durability in outdoor or industrial environments

- Long lead times or unstable supply chains

- Weak support or integration help

- Unclear product roadmaps

And in today's climate, with supply chain shifts, AI-driven UX expectations, and demands for local support, picking a reliable PCAP partner is key to your success in any region.

Whether you're based in:

- North America

- Europe

- LATAM

- Middle East

- Asia-Pacific

Or your product application is for:

- Industrial equipment, EV, kiosk

- Retail, corporate, AV, outdoor

- Banking, public systems, healthcare

- Transport, entertainment, energy

- Gaming, consumer, manufacturing

…the same critical considerations apply.

3) What to Look for in a PCAP Touchscreen Manufacturer

3) What to Look for in a PCAP Touchscreen Manufacturer

Here’s your 2025 checklist:

Here’s your 2025 checklist:

In-House R&D and Production

In-House R&D and Production

Look for a manufacturer that designs and produces its own touch sensors, controllers, and software tools. This means:

Better quality control

Shorter lead times

Faster innovation cycles

Easier product customization

🛠️ Example: At DISPLAX, we manufacture and test all our touch components in-house - from the controller firmware to the sensor design - ensuring total integration and precision.

Look for a manufacturer that designs and produces its own touch sensors, controllers, and software tools. This means:

Better quality control

Shorter lead times

Faster innovation cycles

Easier product customization

Local + Global Support

Local + Global Support

Support matters more than ever, especially when your product enters rugged or regulated markets.

Do they offer pre- and post-sales technical support?

Are they responsive in your time zone or language?

Can they help debug issues during your integration cycle?

👥 Pro Tip: Always ask to speak directly with a support engineer or technician before committing to volume.

Support matters more than ever, especially when your product enters rugged or regulated markets.

Do they offer pre- and post-sales technical support?

Are they responsive in your time zone or language?

Can they help debug issues during your integration cycle?

Proven Track Record in Harsh Environments

Proven Track Record in Harsh Environments

Not all PCAP is created equal. If you're deploying in:

Outdoor kiosks

EV charging stations

Medical settings

Industrial control panels

High-use public areas

…you need a partner with experience in UV protection, glove usage, EMI filtering, thick glass, and multi-user interactions.

🔎 What to ask:

What are your largest deployments?

What’s the thickest glass you support?

What’s your sensor controller’s SNR (Signal to Noise Ratio)?

Not all PCAP is created equal. If you're deploying in:

Outdoor kiosks

EV charging stations

Medical settings

Industrial control panels

High-use public areas

…you need a partner with experience in UV protection, glove usage, EMI filtering, thick glass, and multi-user interactions.

🔎 What to ask:

What are your largest deployments?

What’s the thickest glass you support?

What’s your sensor controller’s SNR (Signal to Noise Ratio)?

Flexible Product Formats

Flexible Product Formats

Demand more than fixed screen sizes. Look for:

Touch sensors from 7” to 135”

Support for custom sizes and shapes

Lamination with or without glass

Support for flat, curved, or drilled glass

Multiple sensor types (wire, mesh, ITO)

💡 Did You Know? DISPLAX offers PCAP touchscreens with glass thicknesses up to 20mm, suitable for industrial-grade, vandal-proof applications.

Demand more than fixed screen sizes. Look for:

Touch sensors from 7” to 135”

Support for custom sizes and shapes

Lamination with or without glass

Support for flat, curved, or drilled glass

Multiple sensor types (wire, mesh, ITO)

Native Multi-OS Support

Native Multi-OS Support

Plug-and-play is critical. Your controller should support:

Windows

Linux

Android

Raspberry Pi

Embedded systems (via USB, I²C, SPI)

And it should be HID compliant - to avoid custom drivers and delays.

Plug-and-play is critical. Your controller should support:

Windows

Linux

Android

Raspberry Pi

Embedded systems (via USB, I²C, SPI)

Certifications and Compliance

Certifications and Compliance

Ensure your partner provides:

CE, RoHS, UL, FCC, and ISO compliance

IK impact ratings (for industrial use)

IP ratings for water/dust protection

And a clear roadmap for future updates

Ensure your partner provides:

CE, RoHS, UL, FCC, and ISO compliance

IK impact ratings (for industrial use)

IP ratings for water/dust protection

And a clear roadmap for future updates

4) Choosing the Right PCAP Partner Isn’t Just Technical - It’s Strategic

4) Choosing the Right PCAP Partner Isn’t Just Technical - It’s Strategic

In a world of AI interfaces, ambient computing, and connected devices, touchscreens are more than input systems, they are experience surfaces.

Choosing a PCAP manufacturer means choosing:

Your long-term product roadmap

Your cost of ownership

Your end-user experience

And your ability to scale reliably

In a world of AI interfaces, ambient computing, and connected devices, touchscreens are more than input systems, they are experience surfaces.

Choosing a PCAP manufacturer means choosing:

Your long-term product roadmap

Your cost of ownership

Your end-user experience

And your ability to scale reliably

Why Global Companies Choose DISPLAX

Why Global Companies Choose DISPLAX

Here’s what sets us apart:

✅ Touch is all we do - we’re not a panel assembler

✅ All R&D and production is done in-house

✅ SKIN ZEETO, TILE PRO, and MESH offer solutions from 7” to 135”

✅ Glass processing is controlled by us — curved, drilled, printed, laminated

✅ Used in 40+ countries across industrial, retail, medical, and EV

✅ Certified, tested, and trusted worldwide

✅ Native support for all major OS

✅ Integrated software: DISPLAX Connect for fine-tuning and diagnostics

✅ Support teams available for Europe, North America, LATAM, Middle East, and Asia-Pacific

Here’s what sets us apart:

✅ Touch is all we do - we’re not a panel assembler✅ All R&D and production is done in-house

✅ SKIN ZEETO, TILE PRO, and MESH offer solutions from 7” to 135”

✅ Glass processing is controlled by us — curved, drilled, printed, laminated

✅ Used in 40+ countries across industrial, retail, medical, and EV

✅ Certified, tested, and trusted worldwide

✅ Native support for all major OS

✅ Integrated software: DISPLAX Connect for fine-tuning and diagnostics

✅ Support teams available for Europe, North America, LATAM, Middle East, and Asia-Pacific

Final Thoughts: Ask These 5 Questions Before You Choose

Final Thoughts: Ask These 5 Questions Before You Choose

Do you build or just assemble touchscreens?

Can you support my glass thickness, format, and usage conditions?

Is your touch controller built in-house and updatable?

What’s your support like post-sale and during integration?

Are your lead times and certifications reliable?

If the answer isn’t clear - let’s talk.

Do you build or just assemble touchscreens?

Can you support my glass thickness, format, and usage conditions?

Is your touch controller built in-house and updatable?

What’s your support like post-sale and during integration?

Are your lead times and certifications reliable?

Want help choosing the right PCAP solution for your project?

Want help choosing the right PCAP solution for your project?

Get in touch with the DISPLAX team for a sample, consultation, or product spec comparison.

Get in touch with the DISPLAX team for a sample, consultation, or product spec comparison.

INSIGHTS

How to Choose the Right PCAP Touchscreen Manufacturer in 2025

DISPLAX Team | June 25, 2025 | 5min

This article outlines the most important factors for selecting a PCAP (Projected Capacitive) touchscreen manufacturer in 2025. The article covers product quality, customization, support, and key differentiators. Learn how to choose the right supplier - whether you're in the US, Europe, Latin America, Middle East, or Asia-Pacific - and avoid costly mistakes.

This article outlines the most important factors for selecting a PCAP (Projected Capacitive) touchscreen manufacturer in 2025. The article covers product quality, customization, support, and key differentiators. Learn how to choose the right supplier - whether you're in the US, Europe, Latin America, Middle East, or Asia-Pacific - and avoid costly mistakes.

Touchscreens are everywhere, powering kiosks, digital signage, medical equipment, EV chargers, industrial machines, and more. But in 2025, not all touchscreen technology - or suppliers - are built the same.

With the rapid exit of key players like Zytronic from the market, and the influx of low-cost alternatives, choosing the right PCAP touchscreen manufacturer is more critical than ever. Whether you're an OEM, system integrator, or product engineer, this guide will help you identify what really matters - and how to make the right long-term choice for your project.

Touchscreens are everywhere, powering kiosks, digital signage, medical equipment, EV chargers, industrial machines, and more. But in 2025, not all touchscreen technology - or suppliers - are built the same.

1) What Is a PCAP Touchscreen Manufacturer?

1) What Is a PCAP Touchscreen Manufacturer?

A PCAP (Projected Capacitive) touchscreen manufacturer designs, builds, and assembles the key components behind interactive touch devices. This includes:

The touch sensor (usually ITO, wire, or metal mesh-based)

The touch controller (which detects touch input and communicates with the device)

And often, the glass and lamination process (the interface the user actually touches)

A true PCAP manufacturer develops these components in-house or controls the full supply chain — rather than assembling parts from third parties.

A PCAP (Projected Capacitive) touchscreen manufacturer designs, builds, and assembles the key components behind interactive touch devices. This includes:

The touch sensor (usually ITO, wire, or metal mesh-based)

The touch controller (which detects touch input and communicates with the device)

And often, the glass and lamination process (the interface the user actually touches)

2) Why Manufacturer Choice Matters (Globally)

2) Why Manufacturer Choice Matters (Globally)

Choosing the wrong supplier can lead to:

- Incompatibility with your system

- Poor durability in outdoor or industrial environments

- Long lead times or unstable supply chains

- Weak support or integration help

- Unclear product roadmaps

And in today's climate, with supply chain shifts, AI-driven UX expectations, and demands for local support, picking a reliable PCAP partner is key to your success in any region.

Whether you're based in:

- North America

- Europe

- LATAM

- Middle East

- Asia-Pacific

Or your product application is for:

- Industrial equipment, EV, kiosk

- Retail, corporate, AV, outdoor

- Banking, public systems, healthcare

- Transport, entertainment, energy

- Gaming, consumer, manufacturing

…the same critical considerations apply.

Choosing the wrong supplier can lead to:

- Incompatibility with your system

- Poor durability in outdoor or industrial environments

- Long lead times or unstable supply chains

- Weak support or integration help

- Unclear product roadmaps

And in today's climate, with supply chain shifts, AI-driven UX expectations, and demands for local support, picking a reliable PCAP partner is key to your success in any region.

Whether you're based in:

- North America

- Europe

- LATAM

- Middle East

- Asia-Pacific

Or your product application is for:

- Industrial equipment, EV, kiosk

- Retail, corporate, AV, outdoor

- Banking, public systems, healthcare

- Transport, entertainment, energy

- Gaming, consumer, manufacturing

…the same critical considerations apply.

3) What to Look for in a PCAP Touchscreen Manufacturer

3) What to Look for in a PCAP Touchscreen Manufacturer

Here’s your 2025 checklist:

Here’s your 2025 checklist:

In-House R&D and Production

In-House R&D and Production

Look for a manufacturer that designs and produces its own touch sensors, controllers, and software tools. This means:

Better quality control

Shorter lead times

Faster innovation cycles

Easier product customization

🛠️ Example: At DISPLAX, we manufacture and test all our touch components in-house - from the controller firmware to the sensor design - ensuring total integration and precision.

Look for a manufacturer that designs and produces its own touch sensors, controllers, and software tools. This means:

Better quality control

Shorter lead times

Faster innovation cycles

Easier product customization

Local + Global Support

Local + Global Support

Support matters more than ever, especially when your product enters rugged or regulated markets.

Do they offer pre- and post-sales technical support?

Are they responsive in your time zone or language?

Can they help debug issues during your integration cycle?

👥 Pro Tip: Always ask to speak directly with a support engineer or technician before committing to volume.

Support matters more than ever, especially when your product enters rugged or regulated markets.

Do they offer pre- and post-sales technical support?

Are they responsive in your time zone or language?

Can they help debug issues during your integration cycle?

Proven Track Record in Harsh Environments

Proven Track Record in Harsh Environments

Not all PCAP is created equal. If you're deploying in:

Outdoor kiosks

EV charging stations

Medical settings

Industrial control panels

High-use public areas

…you need a partner with experience in UV protection, glove usage, EMI filtering, thick glass, and multi-user interactions.

🔎 What to ask:

What are your largest deployments?

What’s the thickest glass you support?

What’s your sensor controller’s SNR (Signal to Noise Ratio)?

Not all PCAP is created equal. If you're deploying in:

Outdoor kiosks

EV charging stations

Medical settings

Industrial control panels

High-use public areas

…you need a partner with experience in UV protection, glove usage, EMI filtering, thick glass, and multi-user interactions.

🔎 What to ask:

What are your largest deployments?

What’s the thickest glass you support?

What’s your sensor controller’s SNR (Signal to Noise Ratio)?

Flexible Product Formats

Flexible Product Formats

Demand more than fixed screen sizes. Look for:

Touch sensors from 7” to 135”

Support for custom sizes and shapes

Lamination with or without glass

Support for flat, curved, or drilled glass

Multiple sensor types (wire, mesh, ITO)

💡 Did You Know? DISPLAX offers PCAP touchscreens with glass thicknesses up to 20mm, suitable for industrial-grade, vandal-proof applications.

Demand more than fixed screen sizes. Look for:

Touch sensors from 7” to 135”

Support for custom sizes and shapes

Lamination with or without glass

Support for flat, curved, or drilled glass

Multiple sensor types (wire, mesh, ITO)

Native Multi-OS Support

Native Multi-OS Support

Plug-and-play is critical. Your controller should support:

Windows

Linux

Android

Raspberry Pi

Embedded systems (via USB, I²C, SPI)

And it should be HID compliant - to avoid custom drivers and delays.

Plug-and-play is critical. Your controller should support:

Windows

Linux

Android

Raspberry Pi

Embedded systems (via USB, I²C, SPI)

Certifications and Compliance

Certifications and Compliance

Ensure your partner provides:

CE, RoHS, UL, FCC, and ISO compliance

IK impact ratings (for industrial use)

IP ratings for water/dust protection

And a clear roadmap for future updates

Ensure your partner provides:

CE, RoHS, UL, FCC, and ISO compliance

IK impact ratings (for industrial use)

IP ratings for water/dust protection

And a clear roadmap for future updates

4) Choosing the Right PCAP Partner Isn’t Just Technical - It’s Strategic

4) Choosing the Right PCAP Partner Isn’t Just Technical - It’s Strategic

In a world of AI interfaces, ambient computing, and connected devices, touchscreens are more than input systems, they are experience surfaces.

Choosing a PCAP manufacturer means choosing:

Your long-term product roadmap

Your cost of ownership

Your end-user experience

And your ability to scale reliably

In a world of AI interfaces, ambient computing, and connected devices, touchscreens are more than input systems, they are experience surfaces.

Choosing a PCAP manufacturer means choosing:

Your long-term product roadmap

Your cost of ownership

Your end-user experience

And your ability to scale reliably

Why Global Companies Choose DISPLAX

Why Global Companies Choose DISPLAX

Here’s what sets us apart:

✅ Touch is all we do - we’re not a panel assembler

✅ All R&D and production is done in-house

✅ SKIN ZEETO, TILE PRO, and MESH offer solutions from 7” to 135”

✅ Glass processing is controlled by us — curved, drilled, printed, laminated

✅ Used in 40+ countries across industrial, retail, medical, and EV

✅ Certified, tested, and trusted worldwide

✅ Native support for all major OS

✅ Integrated software: DISPLAX Connect for fine-tuning and diagnostics

✅ Support teams available for Europe, North America, LATAM, Middle East, and Asia-Pacific

Here’s what sets us apart:

✅ Touch is all we do - we’re not a panel assembler✅ All R&D and production is done in-house

✅ SKIN ZEETO, TILE PRO, and MESH offer solutions from 7” to 135”

✅ Glass processing is controlled by us — curved, drilled, printed, laminated

✅ Used in 40+ countries across industrial, retail, medical, and EV

✅ Certified, tested, and trusted worldwide

✅ Native support for all major OS

✅ Integrated software: DISPLAX Connect for fine-tuning and diagnostics

✅ Support teams available for Europe, North America, LATAM, Middle East, and Asia-Pacific

Final Thoughts: Ask These 5 Questions Before You Choose

Final Thoughts: Ask These 5 Questions Before You Choose

Do you build or just assemble touchscreens?

Can you support my glass thickness, format, and usage conditions?

Is your touch controller built in-house and updatable?

What’s your support like post-sale and during integration?

Are your lead times and certifications reliable?

If the answer isn’t clear - let’s talk.

Do you build or just assemble touchscreens?

Can you support my glass thickness, format, and usage conditions?

Is your touch controller built in-house and updatable?

What’s your support like post-sale and during integration?

Are your lead times and certifications reliable?

Want help choosing the right PCAP solution for your project?

Want help choosing the right PCAP solution for your project?

Get in touch with the DISPLAX team for a sample, consultation, or product spec comparison.

Get in touch with the DISPLAX team for a sample, consultation, or product spec comparison.